When it comes to enhancing the durability, performance, and longevity of components in demanding industries like aerospace, microelectronics, and manufacturing, coatings play a crucial role. Among the many advanced coating technologies available today, Electron Beam Physical Vapor Deposition (EB-PVD) stands out for its precision, versatility, and ability to produce high-quality coatings. But what exactly is EB-PVD, and why is it becoming a go-to solution for so many industries? Let’s dive into the science behind this innovative process and explore its wide-ranging applications.

What is EB-PVD?

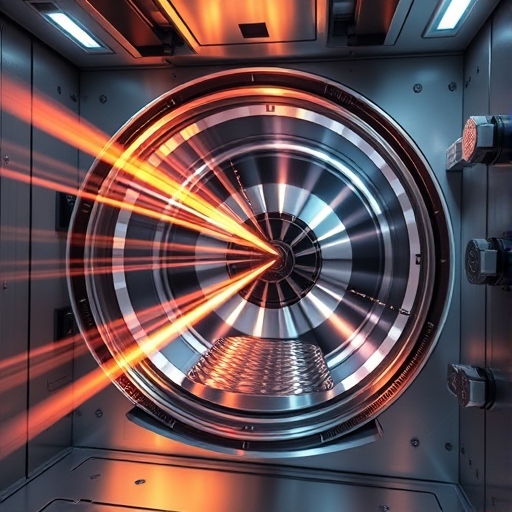

EB-PVD is an advanced thin-film deposition process where electron beams are used to vaporize material (typically metals or ceramics) inside a vacuum chamber. The vaporized material then condenses onto a substrate (like a turbine blade or microelectronic chip) forming a thin, uniform coating. This method offers precise control over the coating’s composition, thickness, and microstructure, making it ideal for a variety of applications where performance and longevity are key.

Unlike some other coating processes that rely on chemical reactions or high temperatures, EB-PVD allows for low-temperature processing, which is particularly advantageous when coating temperature-sensitive substrates.

Why Choose EB-PVD?

EB-PVD stands apart from other common coating techniques, such as Chemical Vapor Deposition (CVD) or metal spray, for several compelling reasons:

- High Deposition Rates: EB-PVD can deposit coatings at rates of up to 150 µm per minute, making it faster than many other deposition methods, such as CVD.

- Dense, High-Quality Coatings: The coatings produced are often dense, uniform, and of excellent quality, reducing defects that can compromise performance.

- Control Over Microstructure: EB-PVD allows for precise control over the microstructure of the coating. This includes creating columnar microstructures and even layering materials with different properties (multilayered coatings or functional gradient coatings).

- Minimal Contamination: The process takes place in a vacuum, significantly reducing the risk of contamination, which is critical in industries like aerospace and microelectronics.

- Environmental Benefits: As compared to processes like chromium electroplating, EB-PVD is more environmentally friendly, eliminating toxic chemicals and reducing waste.

Where is EB-PVD Being Used?

EB-PVD is transforming industries that require high-performance coatings. Let’s take a closer look at some of its most impactful applications:

1. Aerospace: Turbine Engine Coatings

One of the most impressive uses of EB-PVD is in turbine engine coatings. In the aerospace industry, turbine blades are subject to extreme temperatures and environmental conditions. EB-PVD is used to apply thermal barrier coatings (TBCs) that protect turbine blades from oxidation, corrosion, and wear, effectively doubling the lifespan of the component.

The process also allows for multilayered coatings with different properties, such as a bond coat that provides adhesion, followed by a low-conductivity TBC that insulates the component from heat. This helps aircraft engines achieve the Department of Defense’s ambitious goal of doubling thrust-to-weight ratios.

2. Microelectronics: High-Quality Thin Films

In the world of microelectronics, where precision is paramount, EB-PVD is used to deposit epitaxial and textured thin films on semiconductor devices and superconducting materials like yttrium barium copper oxide (YBCO). These coatings act as barrier layers, providing superior electrical properties and ensuring the reliability of advanced electronic devices.

3. Tool and Die Industries: Hard, Wear-Resistant Coatings

Hard, wear-resistant coatings are essential in industries that rely on tools and dies for manufacturing. EB-PVD is used to apply hard coatings like TiC (Titanium Carbide), TiN (Titanium Nitride), and TiAlN (Titanium Aluminum Nitride), which significantly extend the life of tools by protecting them against wear, corrosion, and high-temperature degradation. These coatings can improve tool life by up to 600%, making them a game-changer in industries like automotive manufacturing and metalworking.

4. Optical Coatings: Thin Films for High-Performance Applications

In the optical industry, EB-PVD is used to apply coatings like Ag (silver), Cu (copper), and ZrO2 (zirconium oxide) to components like solar cells and sensors. The resulting films offer exceptional uniformity, density, and surface quality, which are critical for high-performance optical applications.

5. Environmental and Sustainable Coatings: Chromium Replacement

Chromium electroplating has long been a standard method for providing wear and corrosion resistance, but its environmental impact has led to increased scrutiny. EB-PVD is emerging as a sustainable alternative for depositing coatings that offer the same (or even improved) properties without the harmful chemicals associated with chromium plating. For example, the chromium replacement process applied via EB-PVD has shown promise in helicopter landing gear and brass lighting fixtures, offering substantial cost savings and longer component life.

The Future of EB-PVD

As industries continue to push the boundaries of performance, the future of EB-PVD is bright. Researchers are exploring even more advanced coatings, such as superhard multilayered coatings and functional gradient coatings, which could revolutionize applications in industries like aerospace and tool manufacturing. The potential for customized coatings and gradient materials opens up new possibilities for components in harsh environments, from jet engines to nuclear reactors.

Final Thoughts

EB-PVD is a powerful coating technology that is shaping the future of high-performance industries. From enhancing the lifespan of turbine blades to improving the quality of microelectronic components, the versatility and precision of EB-PVD are unparalleled. As the process continues to evolve, we can expect even more breakthroughs in material science, sustainable manufacturing, and industry applications.

Are you working in an industry that could benefit from EB-PVD? Explore how this cutting-edge technology can transform your products and provide a competitive edge in performance and longevity.

Reference:

Electron Beam Physical Vapor Deposition Technology: Present and Future Applications, ARL Penn State’s EB-PVD Technology web site: arl.psu.edu/core/ebpvd/ebpvd.html